Home | Favorites | 中文 | Deutsch |

|

|

|

|

HASL PCB HASL PCB |

|

|

|

|

HASL or hot air solder leveling is a type of finish used on printed circuit boards (PCB).

The PCB is typically dipped into a bath of molten solder such that all exposed copper surfaces are covered by solder. Excess solder

is removed by scraping the PCB with hot air knives.The HASL process consists of a pre-clean, fluxing, hot air leveling, and a post-clean.

Pre-cleaning is usually done with a micro-etch.

Despite the effection of Rohs compliance in 2006, normal hasl finish (hot air solder leveling) is still requested nowadays for special

products or purpose.

Hasl finish has excellent wetting during component soldering which is better than lead free hasl finish; but the hot air solder leveling

on printed circuit board are unsuitable for use with fine pitch components because of low planarity and high thermal stress during

process may introduce defects to pcbs.

Please visit Conventional PCB to check our Surface Treatment finish.

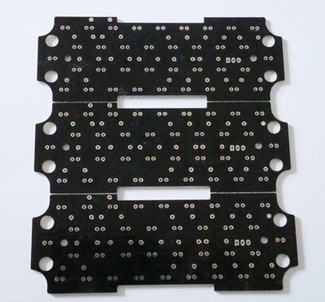

2 Sided Printed Circuit Board

2.40mm board thickness

2OZ finish copper thickness

Normal Hasl surface Finish

Min Track/Space: 6/6mil

Min hole: 0.40mm

Solder Mask: Matt Black

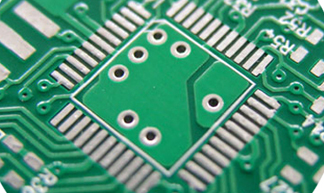

6 Sided Printed Circuit Board

3.20mm board thickness

1OZ finish copper thickness

Normal Hasl surface Finish

Min Track/Space: 4/5mil

Min hole: 0.40mm

Solder Mask: Green

BGA